Andrew Maltby is the President and owner of Biotactics, a company at the forefront of offering integrated pest management solutions. Based in California, Biotactics specializes in breeding predatory mites to help defeat agricultural pests like the widely-loathed spider mite, as well as helping cannabis cultivators prevent and respond to infestations. In this Q&A, Andrew joins us to discuss:

- How Biotactics raises “insatiable” mites that eat much more than typical predatory mites

- Why it’s important to deploy predatory mites as soon as possible once they’ve been cultured

- What Big Agriculture could learn from living soil cannabis cultivators

- How different growing environments can affect infestation risk

- And much more

For the full interview, continue reading below!

How did you get into the business of raising predatory mites?

I actually get asked that quite often. The short answer is that I took over Biotactics after my father retired in 2013. The long answer would be how my family got into the business. That is a story for another day. My family was trained by the founder Glenn Scriven, who was a respected researcher at UC Riverside and a renowned pioneer in the IPM world.

My first stint working at the company was in 2006. I took the summer and fall semesters off from SDSU and worked at Biotactics. My father had just fully implemented our new method of obtaining the pure spider mite eggs. I was tasked with making it predictable, efficient, and basically perfect. At that point, I was about to be a senior in Chemistry major so my lab hands were on point. I spent the whole summer testing exactly what 10, 20, and 30 spider mite eggs per predator would yield. That was when I discovered that there was a possibility to double our culture quantities every 24 hours. Now, that is common practice for us.

What’s behind the name “Benemite” – and what makes them unique?

The Benemite trademark was Glenn’s idea. It is a portmanteau of “beneficial mite.” The mascot used to be a predatory mite with a cape on. That was “mighty mite.” I kept the trademark to signify which predators are reared using our superior food source: spider mite eggs.

To understand what makes Benemite predators unique, you must know how every other insectary raises theirs. Outside of Biotactics, Persimilis is reared the same way. Bean plants are planted, grown, infested with spider mites, they reproduce, then the plant is infested with Persimilis, and they eat and reproduce until there is no food (spider mites) left. Persimilis is known to habitually climb upward in search of food, so they do just that, then they get stuck in a container hanging at the top of the plant. They are starved off the plant, collected, weighed, then shipped to the US from Europe or Africa.

Every other species of predatory mite is reared on what is called a “factitious food source.” These are usually a type of mold mite. If you have ever looked at the contents of a sachet under the microscope then you have probably seen these slow, hairy mini monsters. The spider mite egg is the most nutritious life stage of the most nutritional prey mite. It does not try to run away like the mobile stages, so the youngest predators always have the best food source possible right in front of them.

Biotactics serves cannabis farmers as well as farmers of berries and other agricultural products. How do pest issues with cannabis growing differ from those encountered when growing other crops?

If you want to hear about the problem I had with major insecticides, see the top pinned video on my Instagram page @biotactics. It explains why predatory mites never made it into major farming. (Hint: Neonics make spider mites toxic to predators.)

Pest issues in “Big Ag” are almost worse than in cannabis because the entire monocrop system is built on chemicals. It is ingrained in the culture so much that agronomy students primarily learn which chemicals to use and when. They are taught to fumigate the soil, killing off any beneficial microbes that could be there. Then they need to band-aid over the damage done to the soil with chemical fertilizers. Then they plant seeds treated with systemic fungicides, systemic neonicotinoids, and even more chemical nitrogen.

The pest control practices they are taught are just chemistry lessons, like which chemicals can be mixed with others or sprayed on their own. Instead of fixing the problems created by chemicals, they are taught about which new chemicals fix a given problem that was caused by chemicals used earlier in the season.

It’s not the farmers’ fault that they have been deceived for decades and decades. They need to unlearn generations of education. I do think Big Ag could learn a lot from the cannabis producers I work with. Many cannabis growers are less apprehensive to the idea of introducing more bugs to their crops. They are already familiar with the idea that more life in your mini ecosystem is better than trying to make a clean room in the dirt. We would not have to worry about losing our bees if much of our farmland was switched to living soil.

How do the risks for growers differ based on whether their grow is indoor vs. outdoor, or which medium they use?

Every environment comes with its own challenges. Scouting every day or every other day is the absolute best way to catch a pest issue early. I also recommend small, preventative releases every 2-3 weeks. This way you don’t have to scout as often, and you can let the predators hunt into the hard to reach places.

Outdoor grows seem to have the most resilient plants that I have seen, but then again, they live outdoors so there is always the risk of multiple pests infesting at once. Growers should always attempt to release predators that are native to the area so they can reproduce and overwinter for long term benefits.

Early in the season, the pests are still overwintering so it’s smart to release beneficials like N. Fallacis and Stratiolaelaps that are naturally adapted to cooler climates. Indoor is usually very chemical focused which can lead to a population of what I call “frankenmites.” These are pest mites that are resistant to anything you throw at them, except getting eaten. Even when you rotate sprays you still get resistant populations. Spider mites are especially notorious for this. They have an uncanny ability to develop resistance to chemicals. People say cockroaches will still be alive after a nuclear war, and I think spider mites will be right there with them.

What is the worst-case pest infestation scenario a grower can be exposed to?

Worst case that I have ever seen: severely taco’d leaves that were connected by webbing. They looked like a hotdog with webbing as the condiment. They had a disturbingly large amount of russet and spider mites throughout their entire greenhouse, and they were only three weeks from harvest. That was a memorable day because it was the first time I had ever told a grower that it is unfixable. I ended up using some of his leaves to take some really awesome pictures of our predators attacking russet and spider mites. Shoutout to Erik.Nugshots for coming to the farm that day.

When you’re helping a cannabis grower address a pest infestation, at what point does Biotactics typically get involved? Do you help diagnose the problem, and if so, is this done virtually or in-person?

Great question! I have done quite a bit of online diagnoses using all the same tech that allows people to work remotely, although I always prefer to see large grows in person. It is fun to see the before and after with my own eyes. This happens often via DM through our Instagram page. Sometimes I catch things they don’t see just through experience, other times the webbing gives it away.

I recommend the proper predator(s) once we have nailed down the pest, then I come up with a release rate based on the stage of infestation. I know exactly how many spider mites my predators eat every 24hrs because I know exactly how much I feed them. Other pest mites like russets and broads required testing before I could confidently give a recommendation. This same testing is what taught me that G. Occidentalis can control and reproduce on the Hemp Russet Mite. Still waiting on someone to publish that research though.

What are some of the benefits of locally-raised predatory mites vs. mites shipped from overseas?

We are the only insectary that rears 100% of its predators in the US, in Southern California specifically. This is something we are very proud of. Our growers release our predators within 48 hours of when they leave our cultures. We also require our distributors to send dropship orders: this way it goes straight from us to the grower.

With that said… The main problem with intercontinental transport is the fluctuations of temperature and humidity between when they are packaged at the insectary to when they get released on the end-user’s crop. First they get driven to the airport, dropped off, shipped in the cargo hold of an airliner, then there is usually a several hour long layover, they arrive at the final airport, off-loaded with all the other cargo, transported to a USDA inspection facility, released to the insectary representative, repackaged, then sent to the end user or another distributor who again ships them to the end user. That is four days minimum.

Be wary of sources that have predators on-hand because they most likely have stored them for days already. “Breeding” or “slow-release” sachets make that entire trip with a hole already in the bag. Our healthy predators would have lined the inside of the box before the first plane took off.

Most growers in the US are releasing Persimilis that have gone without food for 4 to up to 10 days. That is why they act so crazy when growers open the bottles. They are literally starving to death. All that time without food causes permanent damage to their reproductive ability. Even in their ideal climate, if predatory mites can’t lay eggs, then they don’t eat. Their field efficacy reflects that biological change.

How do you measure the effectiveness of the mites that you raise? Have you compared their performance to other predatory mites that are on the market?

Two years ago, I donated some of our Benemite Fallacis to a major university entomology lab that was testing a new fungicide on strawberry plants with spider mites. They were testing its effect on various samples of predatory mites. The head entomologist ended up having to re-do the entire experiment because our Fallacis ate all the spider mites in the field so there were none left to keep the other predatory mites around. She said she had never seen anything like it. “They’re insatiable,” she said. So, that was fun.

The best way to determine the efficacy of predatory mites is with the “egg-to-egg” test. Predatory mite eggs are about half the size of their body, and type I’s and II’s can lay up to 5-6 eggs per day. They must eat a whole lot of nutritious food every day in order to do that.

We start with a fixed number of freshly laid predator eggs, usually 10 or 15, of the same species from our insectary and some from another source. Each insectary has its eggs on their own culture tray in the ideal reproductive climate for the species we are testing. We put a very small amount of spider mite eggs near the eggs so when they hatch into nymphs, they have food right away. We keep them fed well throughout the test. We remove the males once they molt into adults and all the females have been fertilized.

Now we have our first data point: the Male to Female ratio. In the wild, this ratio is one male to every three females. However, when food is scarce or poor quality the ratio can be flipped. We have seen this in many samples from every other insectary, especially with Californicus and Persimilis raised on factitious food sources. That is bad for the growers because healthy female predators eat +3x as much food as the males. Every single Benemite species are 75-78% female every single time we have tested them.

Our second data point: the eggs laid per day by the females left on the tray. We count them by removing them from each tray every 16-20 hours. These results are always hard to believe, and I know every other insectary has done these tests internally but will never release the data. On average our Benemite females lay 5 eggs per day. The female predators raised on factitious food sources laid an average of 0.5 eggs per day, or one egg every other day.

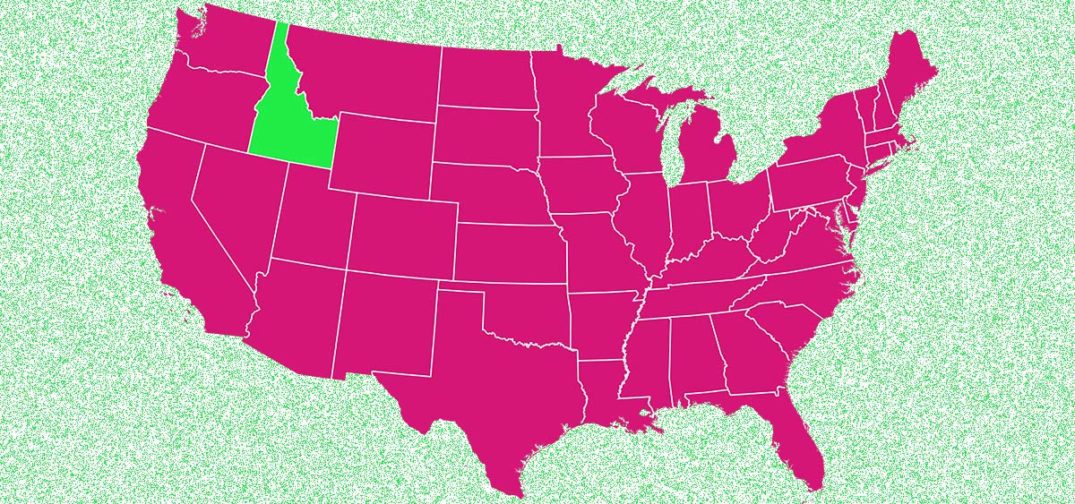

Currently, the regulations governing cannabis growing differ widely from state to state. Looking ahead to a US policy landscape that allows for interstate commerce, how do you think pesticide rules will be affected, and how might a federally-governed regulatory structure differ from what we see at the state level?

While I sincerely hope that the cannabis testing standards stay as high as they are, I am worried that federal legalization will allow it to be lumped in with the rest of agriculture. The agrochemical companies hold a massive amount of power in Washington DC and they have corrupted the governments in the most ag-centric states, even here in California.

Look at California strawberries. They frequently top the “Dirty Dozen” list of pesticide laced foods. The farmers have been lied to for decades under the guise of scientific “research,” though those projects were mostly funded by the same agrochemical companies the “research” promotes. These same companies are directly connected with the pharmaceutical companies, who are creating what many see as human pesticides. Or they make medicine to counteract the symptoms caused by their agrochemical sector.

I think cannabis’ saving grace is the growers themselves. Long-time growers have always been skeptical of the government propaganda, and they know the plant better than any regulator ever could. Their standards are already higher than any test required by law. These pesticide regulations are not for the growers I work with, they are for the growers that struggle to grow literal tons of mids.

My one hope is that systemic insecticides like neonicotinoids will never be legal in any version of cannabis production. Even commercial hemp. Not only are they ineffective against spider mites, but they also make spider mites severely toxic to natural predators. I discovered that the hard way.

To learn more about the predatory mites raised by Biotactics or get in touch, visit their website.