Seven years ago, while building an automated soft pretzel bake & vend machine, a team of 6 engineers realized that they enjoyed designing and building cool stuff together. After their break-out project in June 2013, they established Oat Foundry with a core focus of solving brands’ problems by designing, inventing, and building cool stuff. Now, they are applying their engineering and automation expertise to the cannabis industry.

“There’s always an element of each project where you go ‘Oh, that’s cool’, you know it when you feel it,” said CEO Mark Kuhn. “You could be building a better coffee extraction system or liquid nitrogen ice cream machine, but then you see it, you taste it and realize there’s an elegance in the solution that is really energizing. You look at your coworkers and smile and kind of shake your head and go ‘damn, that’s cool’.”

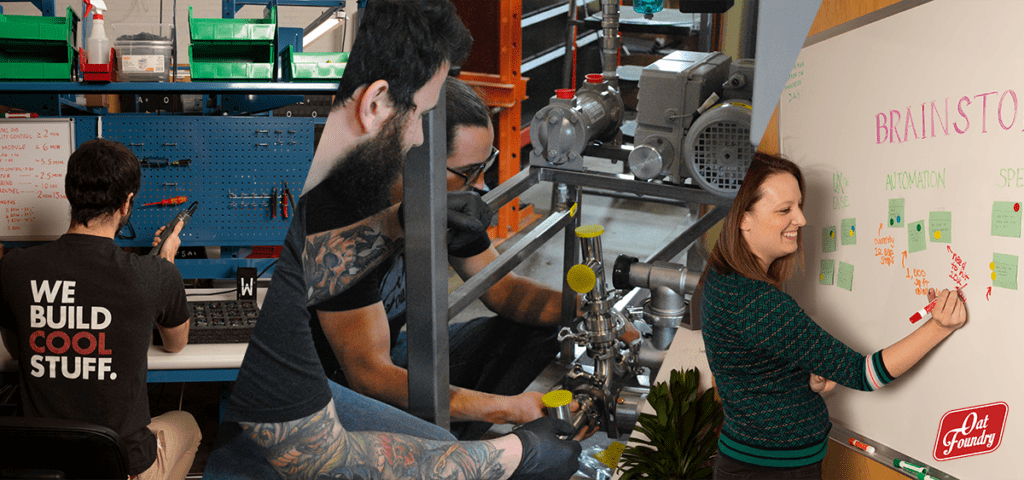

The in-house team at Oat Foundry consists of engineers who consider every aspect of creation, including design, specifications, requirements, problem-solving, and even the math and physics behind potential issues customers may face. “The core team here is excellent in multi-disciplinary system automation and turn-key machine design,” Kuhn said. “Ideation, planning, discovery, user experience mapping, and then moving into actual CAD modeling and putting the nuts and bolts together in a SolidWorks model, making the 3D tech, and even building out product landing pages for clients — storytelling is a huge part of any new venture, whether internally to the boss, or externally to the customers.”

In addition to mechanical engineering, the team’s work often includes electrical engineering to incorporate circuits and computer engineering for cloud integration and telemetry tracking. Their team is capable of sanitary welding, pressure vessel design, PLC ladder logic, and creating intuitive web apps, capabilities they have used in many machines and all of which have direct application in the cannabis industry.

While Oat Foundry’s original focus was on the foodservice and pharmaceuticals industries, their engineers have noticed that the desire to automate and scale is a core concept for cannabis as well. The technology for programmable logic controllers and industrial sensors is the same in cannabis as for any other industry — the only real challenge for cannabis is the industry’s burgeoning legal status. But while the legal challenges have changed how they work with their cannabis clients, it hasn’t hindered Oat Foundry’s abilities. “We love having everyone in the shop, but the pandemic moved everything to fully remote and zoom anyway. We haven’t even missed a beat,” said Kuhn.

Right now, Oat Foundry is building out an extraction machine for SC Botanicals, a South Carolina-based hemp company. The machine pulls THC from bulk plant extract and leaves the CBD, so as to meet stringent guidelines for hemp CBD products and nutraceuticals. For this THC remediation machine they’re shipping the machine designed in Philly to the SC Botanicals lab in South Carolina. This will open up the process to an entirely new set of scientists who will complete process testing while live streaming for the Oat Foundry team, providing real-time input and feedback. The final turn-key machine has increased output to 100L per run and dramatically cut processing time from over 48 hours in a completely automated and hands-off process. This is just their first step into the cannabis space, and the Oat Foundry team is looking forward to taking on more projects.

This sentiment brings us to their core values, the first of which is simply (and understandably): “Build Cool Stuff.” That is followed by Give a Damn – Oat Foundry signed up for food rescues and a zero-waste partnership in their home city of Philadelphia; they also track their plastic use and compost and focus on building products that can be tied back to reducing human carbon output. As they enter the cannabis space, and as part of this core value, Oat Foundry plans to donate funds to organizations set on decarcerating and expunging the records of cannabis prisoners. They live to Grow Purposefully by investing in their employee education with regular innovation missions, thought leadership book clubs, and their innovation podcast Goat Factory. (The podcast has already had some amazing industry guests such as Rosie Mattio of Mattio Communications and Nicole Brown of Open Book Extracts). After these three values, their last core value is to Have Fun, because, according to CEO Mark Kuhn, “We get one life — without the levity of fun, what’s the point?”

In addition to the “Turn Key Automation System” division, the product development team also designs and builds products in the “Kinetic Interactive Sign” division. Their current flagship product is their smart analog signage, a Split Flap display (typically referred to as a departures board, or affectionately as a clack clack clack flippy-flappy board) that adds mesmerizing sound and visual input to any space.

Their Split Flaps have maintained international popularity across a variety of industries — including installations from Azerbaijan, to Hong Kong, to San Diego, in the foodservice, hospitality, retail, office, and hotel industries. The signage is designed after old train station boards that were fed by punch cards, but the Oat Foundry Split Flap can be controlled by a smartphone or point of sale system, allowing it to update in real-time. Their Kinetic Interactive Sign division also created Picture Flap, which is built on the same platform as Split Flap but much larger and to display full-color images.

These signs can also be customized to the client’s desire, creating a uniquely brandable moment. In one case, a bar near the San Diego airport has tapped into the airport data stream to update patrons of flight arrivals and departures. Customers might see a plane fly overhead and know where it is coming from based on the display, or they can also use the tool to make sure they can make it to their gates on time. One of their MLB clients has a sign linked into MLB.com to display real-time sports scores for stadium goers and at a famous NYC noodle bar, the Split Flap design features their “going, going, gone” menu items.

As Oat Foundry enters the cannabis space, they’re confident that their signs can contribute to cannabis dispensaries in new and exciting ways. Modern dispensary design is expensive and intentional, and adding an LED screen menu can bring a lot of extra blue light into a space. Instead of fatiguing customers with the starkness of LEDs, a Split Flap or picture-flap display sign can bring whimsy, entertainment, curiosity, and even fascination to a retailer. Not to mention the sound of the changing letters or images mimics a soothing rain stick or waterfall. Their displays are new to cannabis retail design, so the Oat Foundry team is continually working to understand that which is most important to dispensary owners and operators. This curiosity is a driving force at their Philadelphia headquarters and is essential in their primary mission to build cool stuff and solve problems for their clients.

As Oat Foundry grows, they will continue providing best-in-class kinetic signage like split flap and picture flap, while substantially expanding their automation business. They pride themselves on strong customer relationships — they are the type of company where new and old clients alike can text the CEO and they have their sights set on growth in cannabis. “Let’s leverage our product design, engineering design, programming, automation, and innovation mentality for solving some interesting problems,” said Kuhn.