Pre-rolls have undeniably become one of the fastest-growing categories in the cannabis industry. Consumers seek convenience, and the era of worrying about low-quality cannabis in pre-rolls has faded into the past.

Furthermore, the introduction of cylindrical or cigarette-style pre-rolls (straight pre-rolls) has elevated an outstanding smoking experience, adding to the allure of this category.

With rising sales figures in many states, the need to optimize production becomes paramount, especially in light of limited financial liquidity and workforce availability. The focus shifts towards profitability, cost reduction, increased product quality, and enhanced appeal.

Let’s face it; achieving these goals requires departing from conical pre-rolls and slow-paced automated production. It’s time to draw inspiration from the tobacco and cigarette industry’s rod production methods.

Efficiency and Precision in Cannabis Production

In the 1950s, cigarettes came in various shapes, mostly lacking filters. Brands like Marlboro recognized the potential of filters, appealing to a broader consumer base. Standardizing the cylindrical shape introduced automation, significantly reducing production costs. Today, those early adopters dominate the global cigarette market, and Körber (formerly Hauni), the pioneer of filter cigarette making machines, stands as the undisputed number one machine supplier for this industry.

The question arises: Can this approach thrive in the highly fragmented U.S. cannabis market, challenged by interstate shipments? The answer is affirmative, albeit on a smaller scale. Körber’s CANTOS cylindrical pre-roll efficiently produces 40,000 pre-rolls per 8-hour shift. Leveraging the cigarette shape, it seamlessly integrates with regular cigarette packers. As national legalization approaches, highly automated and efficient production hubs emerge, making it even more enticing for some to transition to the world’s fastest pre-roll maker, the Nano-H, producing over 1,000 pre-rolls per minute.

Continuous Flow Production

Cigarettes are produced in a continuous flow, rather than individually rolled. This principle allows production speeds of up to 20,000 cigarettes per minute while maintaining the highest possible quality. Körber’s pre-roll makers embrace this continuous production principle, with adjustments to handle sticky cannabis. Achieving production costs per pre-roll (including all non-cannabis materials) below $0.02 becomes attainable.

© Körber Technologies

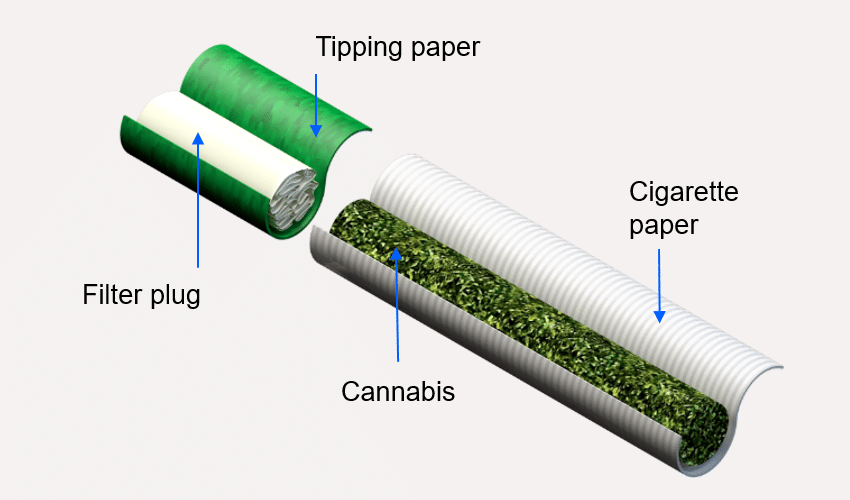

The Filter Plug: Customization and Trends

Upon opening a classic cigarette box, consumers immediately notice the filter plug. Beyond potentially reducing harmful substances, filter plugs enhance pre-roll appearance and flavor. With over 80% of filters worldwide produced on Körber’s filtermaking machines, Körber collaborates with customers to develop innovative filters. These include the capsule filter, featuring a crushable flavor capsule (e.g., mint), and the multi-filter, combining segments like charcoal and acetate. The crimped paper filter plug, once popular in France, has made a comeback due to the demand for biodegradable materials. The crutch tip, commonly found in many pre-rolls, reflects the growing popularity of paper filters. The filter plugs are attached to the cannabis rod by a tipping paper. This tipping paper offers an excellent opportunity for product customization with various colors and logos.

Material Preparation and Airflow Control

Drawing from the tobacco industry’s experience, cannabis production benefits from techniques like resting and cooling to prepare materials for downstream processes. Blending, initially met with skepticism, can however standardizes cannabis characteristics, ensuring a consistent and enjoyable smoking experience, especially with psychoactive substances. With 75 years of expertise in tobacco preparation machinery, Körber applies this knowledge to refine the cannabis preparation process.

Airflow control is a critical factor in mastering the smoking experience. Cigarette companies have perfected the ideal combination of product hardness and airflow to ensure a slow, enjoyable burn. The continuous cigarette production principle, coupled with meticulous filler preparation, enables cannabis companies to achieve similar metrics. Perforated tipping paper or online perforation enhances airflow and can be used in case a lighter taste wants to be achieved.

About Körber

The Körber Group, with over 12,000 employees worldwide, provides machinery and solutions across pharmaceuticals, tissue, and tobacco industries. Körber Logistics offers automated warehouse and parcel handling solutions, while Körber Digital provides AI-based solutions. Körber Technologies (formerly Hauni Maschinenbau), with over 4,000 employees, leads in tobacco machinery and solutions. For over three years, Körber has offered pre-roll makers tailored for the cannabis industry. The compact TFM machine efficiently fills pre-made cylindrical tubes, which are significantly more cost-effective than cones, at 80 cpm. Beyond this, CANTOS and NANO-H are the machines using the continuous cigarette making principle. Körber’s pre-roll makers handle high-THC material and industrial hemp with precision and Körber assist customers in optimizing the entire production process, from material preparation to production flow, as well as the with the selection of the materials (tipping paper etc.).

End